13 5/8-5000PSI HRSB BOP manual Service

Principles of Well Pressure Sealing

A ram blowout preventer can only effectively kill a well when all the four seals have taken effect.

These four seals include the seal between the ram top seal and the body, the seal between the ram

front seal and the pipe, the body and the front seal, the seal between the body and the bonnet, and

the seal between the ram shaft and the bonnet.

The ram sealing process is divided into two steps. In the first step the hydraulic oil forces the ram

shaft to impel the Front Packer rubber element to make it deformed and seal the front part and it

also lets the Top Seal rubber element be interfered and compressed to fill the gap between the Top

Seal element and the body and seal the top, thus finish the primary sealing. In the second step, with

the help of the pressure inside the well the ram is impelled from behind to allow the further

deformation of the Front Packer element and the ram is also impelled from the bottom to let the

body adhere tightly to the Top Seal element and thus achieve the reliable sealing of the well. This is

called the well pressure assisted sealing effect. Rongsheng Machinery Manufacturing Ltd. of Huabei Oilfield, Hebei

7

4. Structures and Features of the Main Components

4.1

Structural Features

² Such major pressure bearing components as the body, the bonnet and the ram block are cast

formed with alloy steels of high strength and high malleability and properly heat treated. And the water

pressure test for strength is performed before ex factory to ensure it can be used safely under the

working pressure.

² At the bottom of the chamber of the body and the ram there are high brace rods and

sand-depositing slots towards the well bore. So the sands and silts can be removed automatically when

the ram is opened and closed. This can reduce the kinetic frictional resistance of the ram and is also

helpful to the well pressure assisted sealing of the ram.

² A kind of floating ram sealing is adopted to reduce the resistance in opening or closing the ram,

minimize the wearing of the rubber elements and lengthen the service life of the ram. It also prevents the

body and ram from rusting together and thus is easy to dismount.

² The parts inside the house of the hydraulic oil unit are embedded to prevent damages to the oil

circuit during the installation, the transportation and the operation of the unit.

² The top seal of the internal chamber of the body is chemically treated for anticorrosion. The circle

slots for the gaskets on the flanges and the sealing disk hollow butt of the ram shaft of the bonnet are

repair welded with stainless steel and the retainers for the sealing disk hollow butt of the ram shaft are

made of a special kind of stainless steel, which is highly corrosion proof.

² The internal parts and surfaces of the blowout preventer in contact with liquids are resistant to the

corrosive stress of hydrogen disulfide and conform to the requirements specified in NACE MR-0175.

²

The dimensions of the external connections are in conformity with the API 6A norms.

4.2

Pipe Ram

There are two kinds of ram assemblies with two different kinds of structures for the F35-35 ram blowout

preventers. One is integral, the new style HF rams and the other is separated, the old style S rams. Both

kinds of rams can be installed and used on the blowout preventer described in this Operation Manual.

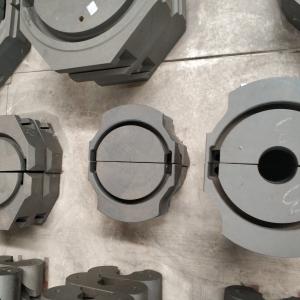

Figure 6 HF Pipe Ram

1

2

3 Rongsheng Machinery Manufacturing Ltd. of Huabei Oilfield, Hebei

8

Table 6 Part List of the HF Ram Assembly

No.

1

2

3

Name

Ram Assembly

Top Seal

Front Packer

Ram Block

Quantity

Ram Specification

1

1

1

C.S.O.

FZ897.21.01.00

FZ897.21.01.01

RJ11148.09.01.02

FZ897.21.01.03

2 3/8"

FZ897.21.02.00

FZ897.21.01.01

RJ11148.09.08.02

FZ897.21.02.03

2 7/8"

FZ897.21.03.00

FZ897.21.01.01

RJ11148.09.02.02

FZ897.21.03.03

3 1/2"

FZ897.21.04.00

FZ897.21.01.01

RJ11148.09.03.02

FZ897.21.04.03

3 1/2", double bore

FZ897.21.10.00

FZ897.21.01.01

RJ11148.09.16.02

FZ897.21.10.03

4 1/2"

FZ897.21.05.00

FZ897.21.01.01

RJ11148.09.13.02

FZ897.21.05.03

5"

FZ897.21.06.00

FZ897.21.01.01

RJ11148.09.04.02

FZ897.21.06.03

5 1/2"

FZ897.21.07.00

FZ897.21.01.01

RJ11148.09.05.02

FZ897.21.07.03

6 5/8"

FZ897.21.10.00

FZ897.21.01.01

RJ11148.09.11.02

FZ897.21.10.03

7"

FZ897.21.08.00

FZ897.21.01.01

RJ11148.09.06.02

FZ897.21.08.03

9 5/8"

FZ897.21.09.00

FZ897.21.01.01

RJ11148.09.07.02

FZ897.21.09.03

10 3/4"

FZ897.21.13.00

FZ897.21.01.01

RJ11148.09.17.02

FZ897.21.13.03

5"-5 1/2"

FZ897.21.11.00

FZ897.21.01.01

RJ11148.09.14.02

FZ897.21.11.03

2 7/8"-5"

RS11172.16.00

RS11172.16.03

RS11172.16.02

RS11172.16.01