Inspection and Maintenance of BOP

Testing, Inspection and Maintenance of BOP II

Testing, Inspection and Maintenance of BOP

2.2 Pressure Tests:

- When performing the low pressure test, do not apply a higher pressure and bleed down to the low test pressure. The higher pressure could initiate a seal that may seal after pressure is reduced therefore misrepresenting a low pressure condition.

- A stable low pressure test should be maintained for at least 5 minutes.

The initial high pressure test on components that could be exposed to well pressure (BOP stack, choke manifolds and choke and kill lines) should be to the rated working pressure of the RAM BOP’s or to the rated working pressure of the wellhead that the stack is installed on, whichever is lower. Initial pressure tests are defined as those tests that should be performed on location before the well is spudded or before the equipment is put into operational device service.

- diverter systems are typically tested to a low pressure only ref to API RP 64.

- Annular BOP’s with a joint of drill pipe installed may be tested to the test pressure applied to the RAM BOP’s or to a minimum of 70% of the annular preventer working pressure, whichever is less. Subsequent pressure tests are tests that should be performed at identified periods during drilling and completion activity on a well.

- The lower Kelly valves, Kelly, Kelly cock, drill pipe safety valves, inside BOP, and top drive safety valves, should be tested with water pressure applied from below to a low pressure of 200 psi – 300 psi then to the rated working pressure.

- There may be instances when the available BOP stack and or / the wellhead have higher pressures than are required for the specific wellbore conditions due to equipment availability. Special conditions such as these should be covered in the site-specific well control pressure test program.

Subsequently, high pressure tests on the well control components should be to a pressure greater than the maximum anticipated surface pressure, but not to exceed the working pressure of the RAM BOP’s.

- A stable high pressure test should be maintained for at least 5 minutes. With larger size annular BOP’s some small movement typically continues within the large rubber mass for prolonged periods after pressure is applied. This packer creep movement should be considered when monitoring the pressure test of the annular.

2.3 Function Tests:

Function test of a piece of equipment or a system to verify its intended operation. Function testing typically does not include pressure testing. Actuation test, operating test and readiness are other terms commonly used synonymously for function test.

All operational components of the BOP equipment systems should be functioned at least once a week to verify the component’s intended operations.

- Function tests should be alternated from the Driller’s panel and from mini – remote panels, if on location (Ref. Appendix A worksheet).

- Actuating time should be recorded as a data base for evaluating trends. (Refer to worksheets appendix A.)

2.4 Pressure Tests:

Pressure Gauges and chart recorders should be used and all testing results recorded pressure Measurements should be made at not less than 25% or more than 75% of the pressure span of the gauge.

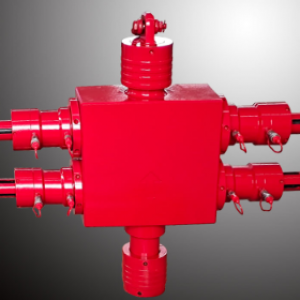

Surface BOP Stack Equipment:

Unless restricted by height, the entire stack should be pressure tested as a unit. Annular BOP’s should be tested with the smaller OD pipe to be used.

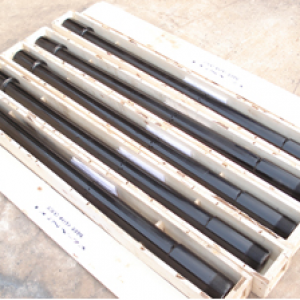

Fixed bore pipe rams should be tested only on the pipe OD size that matches the installed ram blocked,.

Variable bore rams should be initially pressure tested on the largest and smallest OD pipe that may be used during the well operations. Prior to testing each RAM BOP, the secondary rod seals (emergency pack off assemblies) should be checked to ensure the seals have not been energised. Should the ram shaft seal leak during the test, the seal shall be repaired rather than energising the secondary packing.

RAM BOP’s equipped with ram locks should be pressure tested with ram locks in the closed position and closing pressure bled to zero. Manual locks either screw clockwise or counter-clockwise, to hold the rams closed. Hand wheels should be in place and the thread on the ram locking shaft should be in a condition that allows the locks to be easily operated.

2.5 Hydraulic Operator Test

The application of a pressure test to any hydraulic operated component of hydraulic actuated equipment. Hydraulic operator tests are typically specified by the manufacturer for such items as: BOP operator cylinder and bonnet assemblies, hydraulic valve actuators, hydraulic connectors etc. Operating chamber test is frequently used synonymously for hydraulic operator test.

The pressure test performed on hydraulic chambers of annular BOPs should be to at least 1500 psi. Initial pressure tests on hydraulic chambers of ram BOP’s and hydraulically operated valves should be to the maximum operating pressure recommended by the manufacturer.

The test should be run for both the opening and closing chambers.

Pressure should be stabilized for at least 5 minutes.

Subsequent pressure tests are typically performed on hydraulic chambers only between wells or when the equipment is reassembled.

The initial pressure test on the closing unit valves, manifolds, gauges and BOP hydraulic control lines should be to the rated working pressure of the control unit. Subsequent pressure tests of closing unit systems are typically performed following the disconnection or repair of any operating pressure containment seal in the closing unit system, but limited to the affected components.

2.5 Crew Drills

The proficiency with which drilling crews operate the well control equipment is as significant important as the operational condition of the equipment. Crew drills and well control rig practices are address in API RP 59.

Surface BOP Control Systems

Pump Capability Requirements

Each closing unit should be equipped with sufficient number and sizes of pumps to satisfactory perform the operation described in this paragraph. With the accumulator system removed from service, the pumps should be capable of closing the annular preventer on the size of drill pipe being used, plus opening the hydraulically operated choke line valve and obtain a minimum 200 psi pressure above accumulator pre-charge pressure on the closing unit manifold within two (2) minutes or less.