Description

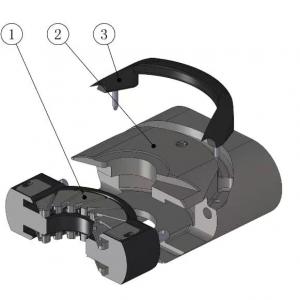

test stump for BOP,QST35J QST105J QST 140J BOP test pump

BOP test stump includes base plates, side and bottom ports, and fixed or removable test mandrel retaining threads.

We offer a wide variety of test flanges and Blow Out Preventer (BOP) test stumps suitable for manufacturers test facilities or drillers testing operations.

Test flanges or BOP test stumps usually incorporate customer specified design requirements to meet customer specific needs.

Available Spec.:

SERVICE: Oil, Gas, H2S Service

SIZE: 7 1/16", 11", 13 5/8", 18 3/4", 21 1/4", etc.

WORKING PRESSURE: 2000 - 15,000PSI

WORKING TEMPERATURE: P-U

MATERIAL CLASS: AA -EE

TEST MANDREL RETAINING THREAD: Fixed or removable

Design Code:

API 6A & API 16A

NACE MR.0175

INSPECTION, QUALITY CERTIFICATE AND AFTER-SALE SERVICE:

1. Inspection:

We adopt factory inspection and on-site inspection. If the product passes on-site inspection, it will enter a warranty period. The inspection conforms to the protocol signed by the two parties and product manufacturing standard. Any kind of third party inspection is acceptable.

2. Quality Certificate:

1) All the equipment are manufactured according to ISO9001 and API standard.

2) Warranty period is 18 months after receiving the goods or 12 months after operation. If there are quality.

problems within warranty period, the supplier is rESPonsible for solving problems in time at any time.

3) If failure and potential safety hazard appear during operation because of designing defect, the supplier will improve the equipment for free.

4) We will provide complete high quality technical document and brochure of the whole equipment in English.

3. Documentations:

1) Traceability Documents: (Including Raw Material Test Certificate, NDT Report, Pressure Test Report, etc.)

2) General Assembly Drawing

3) Technical Service Manual

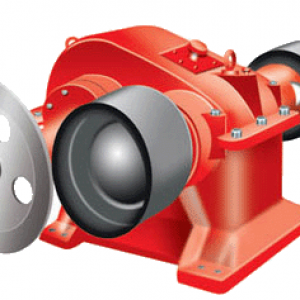

QST105J BOP test pump

Technical Specification for Pneumatic High Pressure Test Unit QST105-J

The unit is designed and manufactured according to the following standard: Q/DSSY 1-2022. Working pressure: 105MPa (15000PSI) (Size:1100×1000×1350mm; N.W:240Kg(529Ib))

1. The unit includes the following parts:

(1) One (1) effective volume 100L oil reservoir, complete with 4〞cleaning port, air filter, oil releasing port and sight glass gauge.

(2) One (1) liquid/air 60:1 pneumatic pump, 1” inlet and 1/2” outlet, working pressure 40MPa, pump flow rate 90mL/stoke.

(3) One (1) liquid/air 200:1 pneumatic pump, which is connected in series with the 60:1 pump to pressurize.

(4) Two (2) M20×1.5 ultra high pressure stop valve, working pressure 140MPa(29000psi), one is used to release the system pressure and the other to retain pressure.

(5) One (1) OD100 pressure gauge with range of 0~200MPa (0~29000PSI).

(6) One (1) 1/2〞air source manifold, complete with stop valve, regulator, air filter and atomizer and two (2) OD60 pressure gauge to display:

a. Air source pressure with range of 0~1.6MPa (0~232PSI);

b. Air pressure for the pump group with range of 0~1.6MPa (0~232PSI);

(7) One (1) chart recorder(0~150MPa), the technical parameters are as follows:

|

Model |

JL-Y-150 |

|

|

Input Signal |

4~20mA |

|

|

Display |

Accuracy |

±0.5%FS±end-term code1 |

|

Function |

Digital display of Measurement value, set value |

|

|

Recording |

Accuracy |

±1%FS |

|

Recording paper |

Linear garden figure recording paper |

|

|

Chart Drive Speed |

2 hours per revolution |

|

|

Control output |

Accuracy |

±0.5%FS |

|

Output Mode |

Relay output:AC 220V/2A DC24V/3A |

|

|

Silicon controlled rectifier output:zero passage trigger pulse output,bi-dictional silicon controlled rectifier output. |

||

|

24V Power output |

DC24V/0.5A |

|

|

Signal transmitting output |

4-20mA |

|

|

Power supply |

AC220V±10% 50Hz |

|

|

Consumed Power |

Less than 10W |

|

|

Operating Environment |

Environment Temperature:-10~50℃ Relative humidity:10%~90%RH |

|

|

Specifications of the test paper |

150MPa |

|

|

Dimension |

Length×width×height 280×280×150mm |

|

(8) One (1) protecting burst sheet, and the bursting pressure is 125MPa.

(9) All other necessary, check valves, bleed valves, fittings and connections for the proper operation of the unit.

(10) one (1) ø13×15m air source hose.

(11) One (1) ø5×15m/180MPa high pressure testing hose.

(12) One (1) 1”×15m water suck-in hose.

(13) One (1) 50m power supply cable.

(14) One (1) set spare part.

(15) One (1) set sealing.

(16) One (1) set dedicated tools.

(17) Chinese and English nameplate.

(18) Two (2) sets of document in Chinese and English.