13 5 8 15000PSI cameron U type ram BOP forging China manufacutuer

13 5/8" 15000PSI cameron U type ram BOP forging China manufacutuerTable 1 Parameters of Ram Blowout Preventer

Item

Single Ram Blowout Preventer

Double Ram Blowout Preventer

Model

13 5/8”

13 5/8”

Top Connection

Studded

Flanged

Studded

Flanged

Bottom Connection

Flanged

Flanged

Flanged

Flanged

Weight Kg

7888

8807

14572

15491

Height (H) mm

1085

1430

1745

2090

Bore Size

346.1 mm (13 5/8″)

Shell Test Pressure

157.5MPa (22,500psi)

Rated Working Pressure

105 MPa (15,000psi)

Hydraulic Control System Strength Pressure

31.5 MPa(4,500psi)

Hydraulic Control System Working Pressure

21 MPa(3,000psi)

Recommended Hydraulic Control Operating Pressure

8.4~10 .5MPa(1,200~1,500psi)

Opening volume for one set of Ram

37L

Closing volume for one set of Ram

40L

Hydraulic Port

NPT 1”

Side Outlet note

3 1/16″-15000psi (it’ll change according to different contract)

Temperature Grade note

T20(-29~121℃) (it’ll change according to different contract)

Closure Ratio

1: 9.5

Other Descriptions:

The designing and the manufacturing of the blowout preventer are in accordance with the API Spec 16A norms.

The resistance to the corrosive stress of hydrogen disulfide of the internal parts of the blowout preventer in contact with the well liquids conforms to the requirements specified in NACE MR-01-75.

Table 2 Specifications of Available Rams

Blind, 2 3/8″,2 7/8″,3 1/2″,4″,4 1/2″,5″,5 1/2″, 6 5/8″, 7″,9 5/8″, Shear

Principles of opening and closing

When high pressure oil of hydraulic control system comes into the left and right closing chambers of cylinders through oil channel inside body from hydraulic port, the impelling Pistons drive ram shafts with ram assemblies to the center of wellhead along ram chamber to close the well. When high pressure oil comes into the left and right opening chambers of cylinders, the impelling Pistons drive the ram shafts with ram assemblies away from the center of the wellhead to open the well. The opening and closing is controlled through the reversal valve of the hydraulic control system.

██ Rams closed, bonnets opened

██ Rams opened, bonnets closed

Figure Hydraulic system opening and closing drawing of rams & bonnets

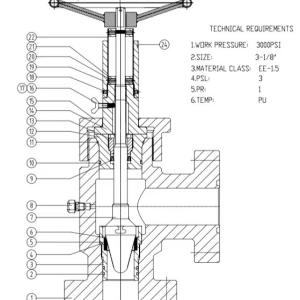

3.2 Principles of well pressure sealing

A ram blowout preventer can only effectively close a well when all the four seals have taken effect. These four seals include the seal between the ram top seal and the body, the seal between the ram front seal and the pipe, the seal between the body and the bonnet, and the seal between the ram shaft and the bonnet.

The ram sealing process is divided into two steps. In the first step the hydraulic oil forces the ram shaft to impel ram packer to deform and seal the front part, and top seal seals top with compressed rubber, so it establishes a primary sealing. In the second step, with the help of the pressure inside the well the rams are impelled from behind to make ram packer deform more and the rams are also impelled from the bottom to let the body adhere tightly to top, thus achieve the reliable sealing. It is called the well pressure assisted sealing effect.

4. Structures and features

4.1 Structural Features

Ø The opening and closing for both rams and bonnets are all actuated hydraulically by one and same hydraulic path. The bonnets’ opening and rams’ closing are actuated by one and same hydraulic path and action; then the bonnets’ closing and rams’ opening are actuated by one and same hydraulic path and action

Ø Ram assembly: ram bodies are in long-round shape. Ram rubber is divided into two parts: front packer and top seal. This structure is easy and convenient for ram rubber to change. The front packer and top seal could be changed rESPectively according to damage condition in fact.

Ø Between body and bonnets, a floating well-pressure-assistant-sealing structure is used on bonnet. So need less pre-tighten force is needed, and it’s reliable.