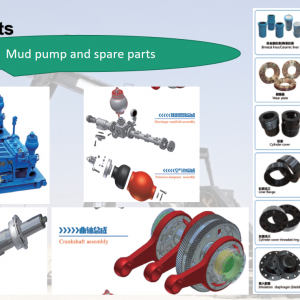

Description

Pinion Shaft and gear shaft

-

High - quality Forged Shaft

- The pinion shaft is forged, providing a solid foundation.

- The standard material is AISI 4340 (40CrNiMo), and customized materials are also available to meet diverse application scenarios.

-

Top - notch Processing Assurance

Top - notch Processing Assurance

- World - class heat treatment technology and multi - spindle CNC machining are employed to ensure that the product quality of the pinion shaft far exceeds API standards.

-

Quality Control

-

Strict Quality Inspection Procedures

- Strict quality control and inspection procedures are implemented to endow the pinion shaft components with better performance and a longer service life.

Gear Machining Process

-

Leading Grinding Process

- The herringbone gear is processed by the grinding process. Compared with the gear hobbing process, it offers better quality and a longer service life, with the tooth surface hardness ranging from HRC55 to 60.

-

Optional Gear Hobbing Process

- The gear hobbing process for the herringbone gear is also available as an option according to customers' needs.

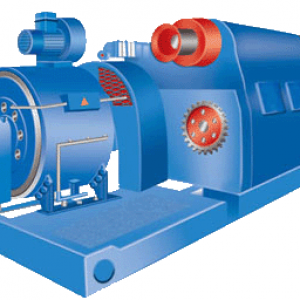

Performance Parameters

-

Suitable for High - pressure Operations

- Specifically designed for drilling operations, with a maximum rated pressure of 7500 PSI.

-

Extremely Long Service Life

- It has an extremely long service life, far exceeding API standards.

Compatibility

-

Full Interchangeability

- It is fully interchangeable with major pump models and power end types.

Product Series

- Fengliang- PE - PS: Fengliang Pinion Shaft, available in full sizes and specifications.

- Customized specific designs and series of HNA Pinion Shaft are available, meeting both API and non - API standards.

-

-

Strict Quality Inspection Procedures