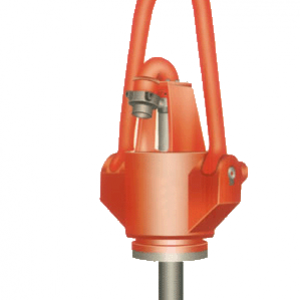

Description

30157221 case of cilinder of top drive

whatsapp:+8613512492572

The Cylinder in the Top Drive is mainly used for the following key functions:

Hydraulic balance system: The hydraulic Cylinder balances the weight of the Top Drive body to reduce the wear of the drill pipe thread.

Brake system: Hydraulic or pneumatic Cylinders control the main Motor brake to ensure the safe positioning of the drill tool during directional drilling or emergencies.

Internal blowout preventer (IBOP) control: Pneumatic or hydraulic Cylinders remotely control the switch of the IBOP to prevent well slugging or blowout.

Back-up Clamp clamping: The hydraulic Cylinder drives the back-up clamp to achieve stable clamping when breaking the Drill Pipe.

2.Fast action: Use compressed air to drive the clamping/releasing mechanism (such as top drive back-up clamp), with a rESPonse time of less than 0.5 seconds25.

3.Auxiliary control: Operate auxiliary equipment such as BOP gates and cooling system valves.

4.Safety redundancy: As a backup Drive unit for the hydraulic system, emergency braking in the event of hydraulic failure.

MODE DETAILS ABOUT THE CYLINDER:

Made of 42CrMo alloy steel (tensile strength ≥ 1080 MPa), the surface is hard chrome plated (thickness 30~50μm) to improve wear resistance and corrosion resistance.

Working Pressure:

Reason for pressure difference: The hydraulic system design of different top drive models (such as balance cylinder, brake cylinder, etc.) has different pressure requirements. For example, deep wells or high-pressure environments may require higher pressures.

2.Pneumatic system pressure

Typical range: If the top drive uses pneumatic cylinders (such as IBOP control), its working pressure is usually between 0.6 MPa and 0.8 MPa (about 87 psi to 116 psi), which is consistent with the industrial standard pneumatic system.

Special scenario: Some top drives' IBOP control cylinders may withstand higher pressures, such as 10,000 psi to 15,000 psi (about 69 MPa to 103 MPa), but this refers to the rated pressure of the valve, not the working pressure of the cylinder itself.

Application scenarios:

Offshore drilling platforms: Top drives need to cope with greater torque and pressure, and the hydraulic system pressure may be close to 35 MPa.

Conventional drilling on land: The hydraulic system pressure is usually between 16 MPa and 20 MPa.

Industry standards:

Top drive design follows (American Petroleum Institute) standards, such as Spec 8C, which clearly stipulates the pressure test and safety requirements of hydraulic systems.

Domestic standards such as SY/T 6870-2021 "Installation, commissioning and maintenance of top drive systems for oil and gas drilling equipment" also put forward requirements for hydraulic system parameters.

Practical operation and maintenance suggestions

1. Pressure monitoring:

Regularly check the pressure value of the hydraulic system to ensure that it is within the range specified by the manufacturer. For example, the hydraulic pressure of the Hi-Sea top drive needs to be maintained at 16 MPa.

The pneumatic system pressure needs to be maintained at 0.6 MPa to 0.8 MPa to avoid damage to components due to excessive pressure or too low pressure to affect the function.

2. Abnormal handling:

If the pressure is abnormal (such as sudden pressure drop or fluctuation), it may be hydraulic oil leakage, valve failure or sensor failure, and the machine needs to be shut down for inspection immediately.

For IBOP control cylinder, if remote control fails, the lower IBOP needs to be manually closed and the pneumatic pipeline needs to be checked for blockage.

3. Lubrication and cleaning:

The hydraulic system needs to use anti-wear hydraulic oil (such as N32) that meets standards and is replaced regularly to maintain pressure stability.

The pneumatic system needs to be equipped with an oil mister to prevent internal wear of the cylinder.

Precautions

Safety specifications:

Top drive operations must strictly follow standards and manufacturer manuals to avoid equipment damage or safety accidents caused by overpressure operation.

Warning signs must be set up in high-pressure areas, and operators must wear protective equipment.

Environmental adaptability:

In cold areas, hydraulic oil must use low-temperature antifreeze type to prevent pressure fluctuations.

In high-temperature environments, heat dissipation Measures must be strengthened to avoid overheating of hydraulic oil and pressure drop.