Hydril MSP Annular BOP 21 1/4-2000PSI Manual Service and manitenance

Hydril MSP Annular BOP 21 1/4-2000PSI Manual Service and manitenance

supplied by Cangzhou Fengliang Petroleum Machinery Co.,Ltd

21 1/4"-2000psi Annular Blow out Preventer must be equipped with hydraulic control system to use. It is usually used with ram BOP, but it can be used solely. It can complete following operations:

Ø It can seal on almost any shape or size: Kelly, drill pipe, tool joints, drill collars, casing or wire line.

Ø When there is no drilling tool in preventer, it can completely shut off the hole.

Ø With an accumulator, forced tripping with 18°/35° welded tool joints is allowed It could be used as a diverter system equipping with a diverter spool.

1. Specifications and technical parameters

1.2. Temperature grade of metal material:

List 3 Temperature grade of metal material

|

Temperature grade code |

API code |

Working temperature range |

|

T75 |

75 |

-59~121℃(-75~250 ºF) |

|

T20 |

20 |

-29~121℃(-20~250 ºF) |

|

T0 |

00 |

-18~121℃(0~250 ºF) |

1.3. Temperature grade of non-metal sealing parts contacting well fluid.

Two-letter combination denotes the highest limit and the lowest limit. Descript it as following:

|

The lowest limit (No. 1 position) |

The highest limit (No. 2 position) |

|

A 15℉(–26℃) |

A 180℉(82℃) |

|

B 0℉(–17.8℃) |

B 200℉(93℃) |

|

C 10℉(–12.2℃) |

C 220℉(104℃) |

|

D 20℉(–6.7℃) |

D 250℉(121℃) |

For example, BB indicates temperature grade from –17.8℃ to 93℃. The concrete temperature grade signs code on the sealing parts.

1.4. Technical parameters

The structure of 21 1/4”-2000PSI Annular BOP is Model A. It can reliably seal on almost any shape or size pipe and can also seal a hole without anything in it. Forced tripping is allowed when the BOP is shut. Reliable sealing, high working pressure, easy to operate and maintain & swift to close and open is its advantages.

TECHNICAL PARAMETERS of 21 1/4”-2000PSI ANNULAR BLOW OUT PREVENTER

(MODEL A)

|

Item |

Parameters |

|

Bore(mm) |

539.7 (21-1/4″) |

|

Working Pressure (MPa) |

14 (2,000psi) |

|

Shell Test Pressure Factory Only (MPa) |

21(3,000psi) |

|

rated working pressure of Hydraulic control (MPa) |

21 (3,000psi) |

|

Recommended hydraulic control working pressure for sealing pipe (MPa) |

≤10.5 (1,500psi) |

|

Max. working pressure for sealing a well without pipe in (MPa) |

7 (1,000 psi) |

|

Recommended hydraulic control working pressure for sealing a well without pipe in (MPa) |

≤10.5 (1,500psi) |

|

Max. Volume for Opening (L) |

84.9 |

|

Max. Volume for Closing (L) |

136.5l |

|

Hydraulic Port |

NPT 1″ |

|

Temperature grade of metal |

T20(-29℃~121℃) |

|

Well Fluid |

Meet NACE MR-01-75 |

|

Parameter

Model |

Top Connection |

Bottom Connection |

Weight (kg) |

Dimension(mm) |

||

|

A |

B |

C |

||||

|

21 1/4”- 2000PSI |

21-1/4″-2,000 6B R73 Studded |

21-1/4″-2,000 6B R73 Flange |

7660 |

1380 |

1437 |

1512 |

Notes: 1. The flanged type is per to standard of API 16A.

1. Working Principle

When there is the need of sealing well upon kick, the high pressure oil (10.5MPa) from the hydraulic control system enters the closing chamber at the bottom of piston through the lower hydraulic port to push the piston upward to force the element to move towards center, the segments close together to extrude the in-between rubber to the center of wellhead to seal drilling tools or full wellbore. When opening, the hydraulic control pressure oil enters the opening chamber at the top of piston through upper oil inlet to push the piston downward, the element returns to original position under the action of its own elasticity and opens the wellhead.

2. Features of structure

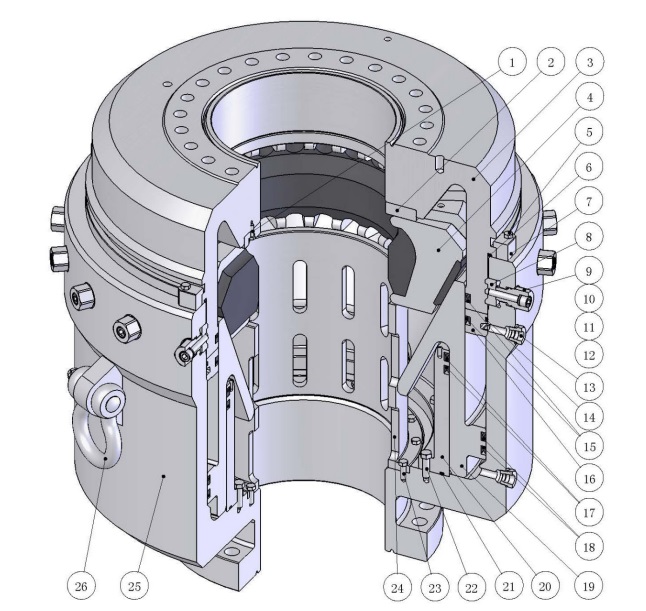

Please see figure 2 &3 for details.

2.1. Simplicity and reliability of structure

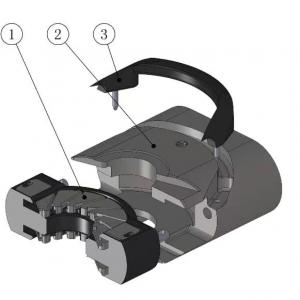

21 1/4”-2000psi annular BOP is constituted by 6 main parts of body, head, piston, outer sleeve, jaw and packing unit. The number of parts is small to enable the BOP to be more reliable and easy for service, and the cover and the shell are jointed by claw chuck, so it is convenient to be dismantled on site. (Refer to Figure 3)

2.2. Compact structure

Only two(2) joints for hydraulic connection “close” & “open”, easy to operate;

Light weight.

2.3. Lip seal structure

All of the power seals are lip structure that could reduce the wear greatly. This structure is more reliable to avoid leakage.

2.4. Trim H2S

The part inside the BOP which will touch the drilling fluid can trim H2S, meeting the NACE MR-01-75 requirements

2.5. Packing unit

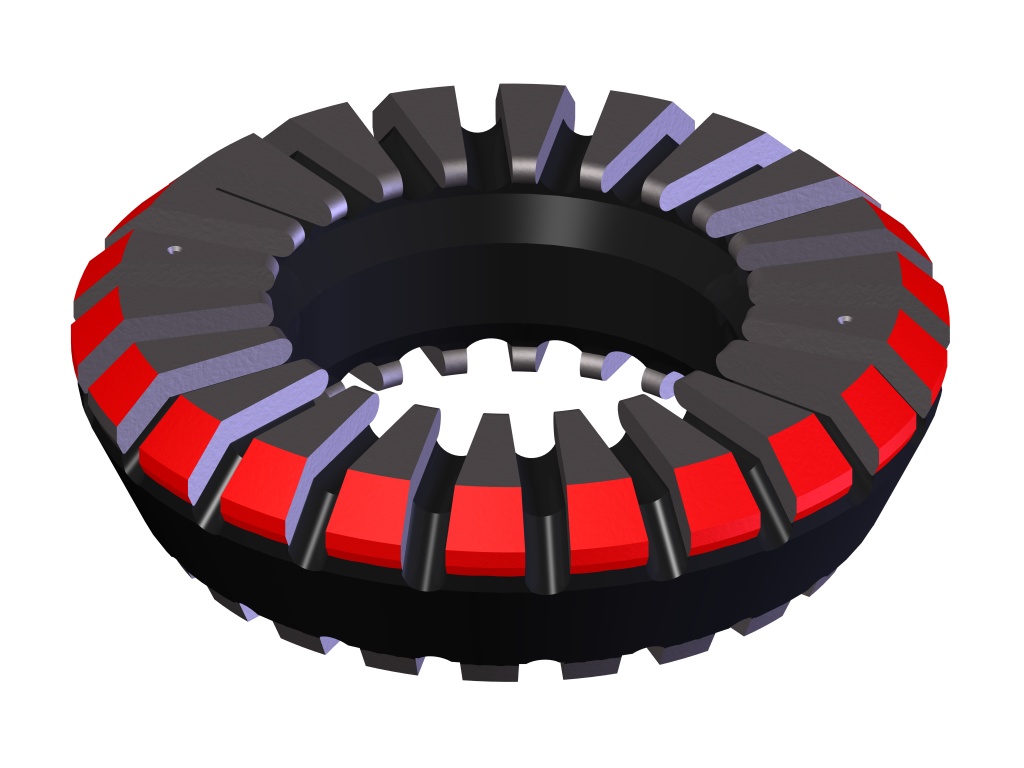

(1) The element is in tapered shape, produced with segments and vulcanized rubber, and the molded-in segments are made of alloy steel. It’s of long service life. (Ref. figure 4)

1. Segments 2. Rubber

1. Segments 2. Rubber

Figure 4 Packing unit

(2)stabilization: During sealing condition, the well pressure will force the central rubber of rubber to turn upward, but the upper bars of segments will stop such turn to keep the rubber in the safe and compressed status, so the packing unit could bear larger pressure without tearing.

(3)Assistance of well pressure for sealing: During closing period, the well pressure acting on the annular area in upper part of inner cavity of piston will push the piston upward, which promotes the tight sealing of rubber, enhances the reliability of sealing, and therefore reduces the pressure on closing and opening of hydraulic control.

(4) If the packing unit needs to be changed and there are drilling tools inside well, the old packing unit could be cut an opening between two segments, and taken out. Then the new packing unit will be cut an opening also, then put in BOP around the drilling tools. (Ref. figure 5)

Figure 5 Cutting between segments

3. Operation and maintenance

3.1. Installation

Following systems are required at well site to use the annular BOP.

⑴ Hydraulic control system;

⑵ Control hoses to the closing hydraulic port;

⑶ Control hoses to the opening hydraulic port;

⑷ For stripping, an accumulator bottle is required. The bottle should be pre-charged with nitrogen to a special pressure

⑸ To meet any situation, a hydraulic regulator should be equipped to adjust operating pressure.

3.2. Stripping operation

Stripping operations are undoubtedly the most severe application for any preventer, because the packing unit will wear greatly as the drill string move through the preventer under pressure. To prolong sealing element life, it is important to use proper operating procedures when stripping. The recommended procedures are as follows:

⑴ Close the preventer with 1500psi closing pressure.

⑵ Just prior to stripping operations, reduce closing pressure to a value sufficient to allow to a slight leak. The slight leak can provide lubrication and prevent excessive temperature build up in the element. As the element wears too much, the operating pressure will need to be incrementally increased to prevent excessive leakage. Note: only string with 18°tool joints could be used, and the tripping speed could not exceed 0.2m/s.

⑶ If conditions will not allow leakage during stripping operations, the closing pressure should be adjusted to a value just sufficient to maintain a seal;

⑷ As required closing pressures approach 1,500psi, excessive leakage still exists, it is said that the rubber has been worn seriously. It must be solved first, and then stripping operations could be continued.

3.3. Proper application

⑴ After installation at well site, the BOP should be pressure tested according to related standards.

⑵ After reaching the target stratum, the BOP should be checked by closing and opening it every two stripping. If there is any problem, it must be solved immediately.

⑶ When a blowout happens with drill string in the well, the annular BOP can be used to control the well pressure first, but it can’t be used for a long time because the service life of the rubber will be shorten greatly, and it does not has locking system.

Normally, don’t use the BOP to shut off a well without pipe in.

Caution: shutting off an empty well completely, the max well pressure should be half of the rated working pressure.

⑷ When the BOP sealing a pipe string, the drill string could move up and down, but the rotation of drill string is forbidden.

⑸ Do not release well pressure by opening annular BOP to avoid rubber damage

⑹ Every opening procedure, its full opening position must be checked to avoid rubber damage.

⑺ Opening and closing operation must use hydraulic oil, and the oil must be kept clean;

⑻ the recommended max operating pressure is 1500PSI (10.5MPa).

4. Parts and disassembly

4.1. Disassembling procedure

4.1.1. Change of packing unit

(1)Reverse jaw operating screw (Item 9)for 5 rounds,then tighten the jaw holding cap screw(Item 10) to take the jaws(Item 8)out of head and disassemble the plug or pipe to hydraulic port.

(2)remove screw and head clamp(Item 5,7)

(3)Lift head out evenly;

(4)Screw the eyebolts into the packing unit and lift it out. If there are drilling tools in it, the new and old packing unit should be cut a opening between two segments with rubber cutter and crowbar first, and rubber cutter should be lubricated with suds (Ref figure 6). Such blunt cutting tools as saw blade etc are forbidden. The cutting surface should be smooth. Then lift the old packing unit out and put the new one in BOP.

4.1.2. Disassembling procedures of piston and piston inner sleeve

(1)after removing packing unit, screw eye bolt in dust proof ring and lift it out evenly;

(2)after removing packing unit, screw eye bolt in piston and lift it out evenly;

(3)remove the screws which connect body and piston inner sleeve(item 22), then piston inner sleeve could lifted out.

4.2. Assembling procedure

1. Check whether the seal rings are ok, they should be changed if they are damaged or aged;

2. Lubricate the inner surface of body, piston and outer sleeve by mechanical oil, brush grease on jaw.

3. Install the piston inner sleeve in and fix it;

4. Install piston in

5. Install packing unit in. The packing unit’s surface should be coated with aluminum base grease or drill pipe sealing grease;

6. Install head. The head’s inner surface should be coated with aluminum base grease or drill pipe sealing grease;

7. Install head by screw and head clamp(item 5、7);

8. tighten jaw operating screw(item 9, recommended torque is 400-540N.m), during tightening, relieve the screw(item 10)first, and at last tighten them

9. Screw on a plug on the hydraulic port avoiding garbage entering (inlet of closing and opening)

5. Proper storage of rubber parts

The storage condition will influence rubber parts’ service life greatly. The perfect storage condition is a cool, dark and dry warehouse and the rubber parts should be packed in bags. All rubber parts should be stored as following if you do not have perfect conditions:

1. Always use the oldest rubber part first. New parts should be placed at the back of the bin, so that old parts will be used first.

2. Definitely do not store rubber parts out of doors. Rubbers should be stored in dark, cool (0-25ºC) and dry room (humidity is less than 80%). Keep them away from heaters and direct sunlight

3. Do not spill corrosive material on rubber parts; Keep storage area as cool as possible. Never store rubber parts near heaters, steam pipes, radiators or other hot equipment.

4. Store these items away from high-voltage equipments. High-voltage equipment frequently produces ozone that attacks rubber.

5. Rubber parts should be placed in a relaxed position. Do not bend, extrude or hang them. For example, bending a rubber part and forcing it into a small box will accelerate aging the stressed area.

6. Check rubber parts often, the parts with brittleness, crackle, bending should be abandoned.

7. Generally the storage period is 2 years.

6. Trouble shooting

6.1. The rubber can not seal pipe completely

⑴ If a new packing unit could not seal pipe completely, it could be opened and closed for several times to improve its flexibility, and then it will be ok. But it should be changed if it still can’t seal pipe completely even all steel segments close together completely.

⑵ If the rubber is over worn or damaged, it should be changed in time

⑶ If a BOP has been opened for a long time, some garbage will fill in the grooves of packing unit and block its movement. The packing unit should be cleaned, and then opened & closed for several times to solve this problem.

6.2. The BOP can not opened after closing

It’s due to the packing unit’s permanent deformation because of long time closing or the concretionary cement under packing unit after cementing. Cleaning or changing packing unit will solve it.

6.3. The BOP can not be opened and closed flexibly.

⑴ Prior to connecting, All pipes should be blew with pressure air. All connectors should be cleaned.

⑵ The hydraulic oil leakage, long-time inaction and blocking up will weaken the flexibility of operation. So BOP must be operated according to the operation procedure.

When ordering an annular blowout preventer, the following should be detailed:

1. Bore size and working pressure

2. Connection type: Top and Bottom connection size, working pressure and ring groove size;

3. Working temperature range: Include metal & rubber parts temperature grade;

4. Ring grooves needs to be lined with stainless steel or not;

5. Requirements of resistance to Hydrogen sulfide;

6. Additional spare parts;

7. Other special requirements: such as metric or British system (for thread and screw).